Encapsulation of Mass Timber with Intumescent Coatings

Comprehending mass timber structures — a foundation to a reliable passive fire solution, Part 1 of 3.

Wood is one of the oldest building materials in the world but it is also the material of the future. Engineered Wood Products (EWPs) are currently challenging the status quo of the construction industry like nothing else and are taking this humble material to the next level.

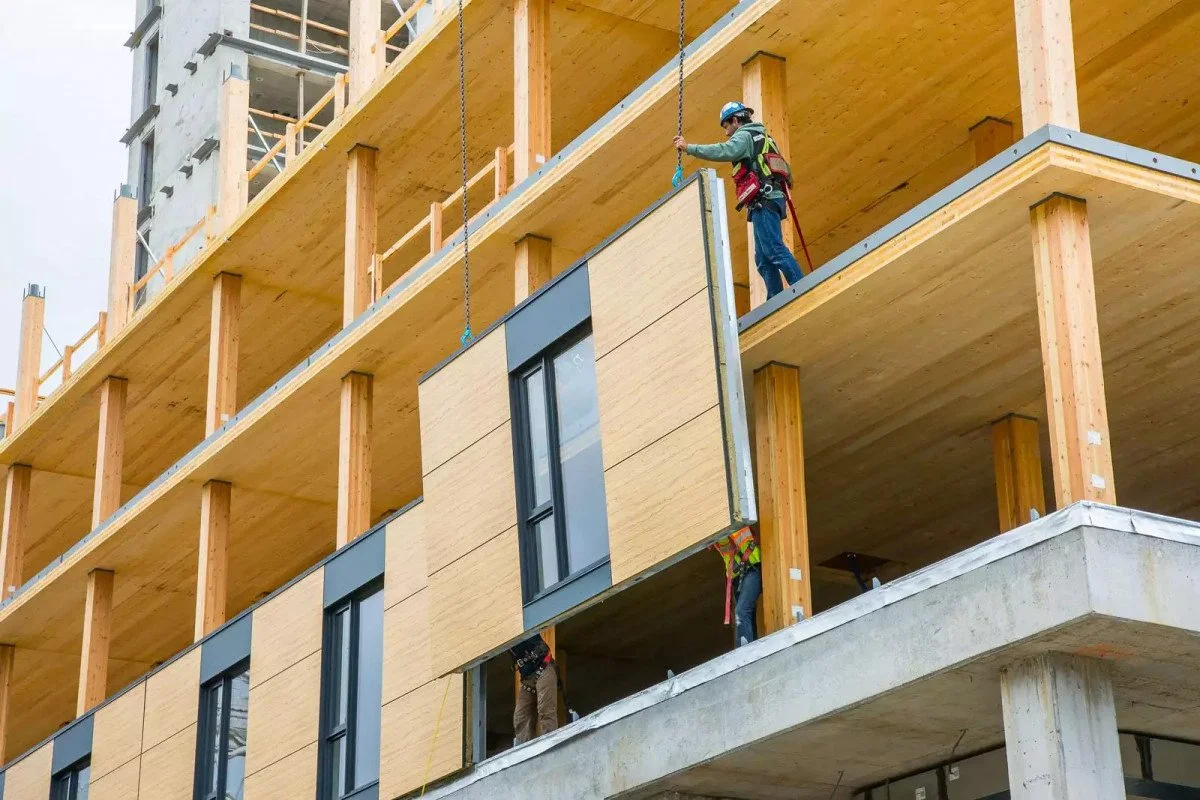

They bring the benefits of wood to larger, taller, and more complex buildings, especially in high-rise urban settings. Designers and engineers now have the ability to build practically any type of building using timber — from multi-purpose residential projects and commercial office spaces to public buildings like schools as well as increasingly tall towers.

The number of mass timber buildings has been growing worldwide as developers strive for more sustainable and efficient methods of construction. When compared to other materials, EWPs provide several advantages: Lighter builds, highly precise production with offsite prefabrication, and faster overall construction times which further reduces costs.

Mass timber also allows for a quieter construction site, involves a smaller work crew and is safer overall. Using mass timber ticks all the boxes — it is sustainable, it is clean, it is quiet, it is fast, it is pleasing to the eye, and let’s not forget, it is safe.

Holistic passive fire solutions for mass timber buildings

Our job as a provider of intumescent coatings is to establish, whether our current solutions can meet the passive fire safety requirement of a project. Consequently, one would expect us to merely focus on the properties of a specific substrate and how to achieve a “fire resistance rating” for a particular element.

Unfortunately, this is often what happens in construction, where we tend to have a narrow focus on the question in front of us. We neglect to communicate with other disciplines and to consider relevant aspects of the wider construction process. Often, time is a crucial factor in this.

But this approach is limited, and our answers will always be restricted in their real-life applicability, as we have not fully considered the critical overlaps with other disciplines.

This singular view will, in the end, not provide a beneficial solution to the customer. It will most likely be missing the links between our and the solution of other disciplines. In the best-case scenario these singular solutions might align, but more often than not, we will encounter quite substantial issues at the interfaces later on.

To overcome this, we strongly advocate to the industry for a more holistic approach.

We see two significant steps to integrate a more holistic process:

Narrow: Start by offering a “system”, which entails integrating the solutions of other disciplines that are closely related, into your own solution e.g., in our case, passive fire stopping.

Wide: Evolve your “system” by further integrating aspects of the wider building framework, e.g., the building schedule, DfMA processes and construction phases.

The first of the above steps should be considered the absolute minimum and put into action as soon as possible, the second could be a longer-term goal. We believe this approach to be an essential aspect to improve building practices and move into the future. Only with cross-disciplinary collaboration will we accelerate progress.

Mass timber construction: An integrated system

The foundation for providing a compliant passive fire solution in CLT buildings means understanding structural fire design.

This starts with considering the objectives of owners who wish to utilise EWPs in their build e.g., incorporating exposed timber to provide for a more natural living space. It furthermore includes taking into account how the initial design is then translated into structural elements utilising a ‘Design for Manufacture and Assembly’ process.

Additionally, providing an adequate passive fire solution means, comprehending the actual material make-up of a classic mass timber building.

In CLT buildings you would normally find a concrete foundation, providing a reliable moisture barrier, and often a combination of structural steel and EWPs (the floors and walls would be made from an EWP) as the loadbearing elements.

A component of paramount importance in CLT floors and walls are steel connectors. Angle brackets, base connections, fasteners and plates all play a vital role in the structural stability in mass timber construction i.e., when panels that are manufactured to optimise transport and installation will need to be connected once onsite.

As these connectors fulfil a multitude of functions, and are designed to account for, not only structural design, but also aesthetics, constructability, accommodations for shrinkage and swelling, seismic characteristics and moisture protection, they need to be a focal point in passive fire protection.

Linings, such as plasterboard, tend to be more sparsely utilised in EWP structures to expose as much timber as possible and to allow for a more natural living space. We will discuss the impact of exposed timber for passive fire safety further down.

In comparison to traditional building methods, there is not much difference when talking about through and partial penetrations. The timber panels are penetrated to allow for services like plumbing, electrical cables, telecommunications, heating, and cooling to pass through the building.

Last but not least, we want to bring awareness to the specific building schedule applied in the mass timber build process. Due to sequencing and utilising the Design for Manufacture and Assembly (DfMA) process, mass timber construction is highly structured and drastically shortened. The schedule is optimised by using off-site fabricated panels with just-in-time delivery. Manufacturing is providing precisely engineered elements, allowing for simplified assembly and a fast build, which sees several stories completed a day.

Comprehending the make-up and interplay of all these elements is essential to providing an adequate and compliant passive fire solution.

Fire properties of engineered wood products

To fully understand the passive fire requirements in an EWP building, we need to zoom in and understand the function timber itself, plays during a fire event. The behaviour of timber in a fire seems, however, contradictory.

Timber, on the one hand, is a natural insulator (with better insulative performance than e.g., concrete or steel) and offers a natural fire-resistance.

Let’s look at this statement in more detail.

When wood begins to heat up due to a fire event, Pyrolysis* (see below) starts to occur, and a black outer layer is formed, which is called char.

This char layer acts as an insulator which slows down the burn rate and protects the core of the timber element. The rate with which the timber chars (char factor) and insulates is highly predictable. Nevertheless, the timber member is still losing strength, and with the reduced cross-sectional size, might become unstable.

For this reason and for structural purposes, mass timber elements are traditionally designed so a sufficient cross-section of wood remains to sustain the design loads for the required duration of fire exposure.

Timber, on the other hand, constitutes a combustible material. Therefore, where it forms large parts of a building’s surface area, it can contribute significantly to the fire/fuel load. This changes the fire dynamics within the building.

What does this mean for structural fire-design?

When designing a building, timber members can either be fully/partially exposed or encapsulated.

While the fire-load can be controlled through limiting the amount of fully/partially exposed timber in a building, based on theoretical calculations, protecting the timber with a fire resistant insulative material (encapsulation material) is isolating the timber from the ignition source without restricting its use.

The takeaway from this is that large-scale and tall mass timber structures can be designed safely, including in the event of fire. And encapsulation is an essential tool in achieving this safety.

Conclusion

Mass timber is inspiring the most recent innovation in the building industry and with that advancing a change in thinking. A change that is urgently needed, especially in an industry that is so averse to change. More than ever, collaboration and the sharing of knowledge is essential to create a truly beneficial solution.

With this article we wanted to start our series and enhance the willingness for this change.

In our next article we want to show the audience why encapsulation is a crucial element when talking passive fire protection in mass timber buildings and how a thin-film intumescent coating can offer fire-safety early in the construction process.

* Pyrolysis is the slowest rate of oxidation which can take place and cause a fire and consists of the destruction of wood through the application of heat in the presence or absence of oxygen.