TESTING OUR PRODUCT,

NOT YOUR PATIENCE

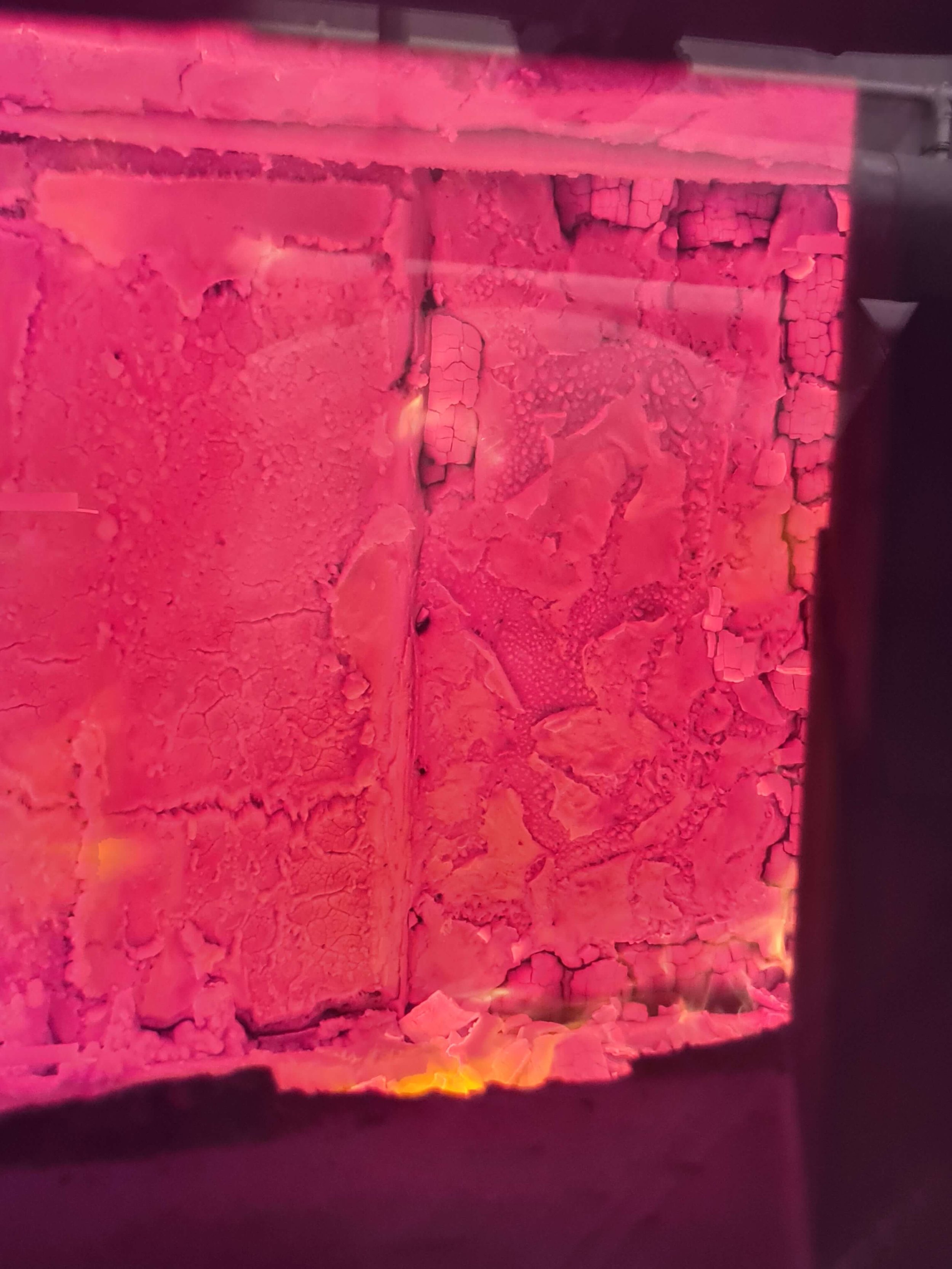

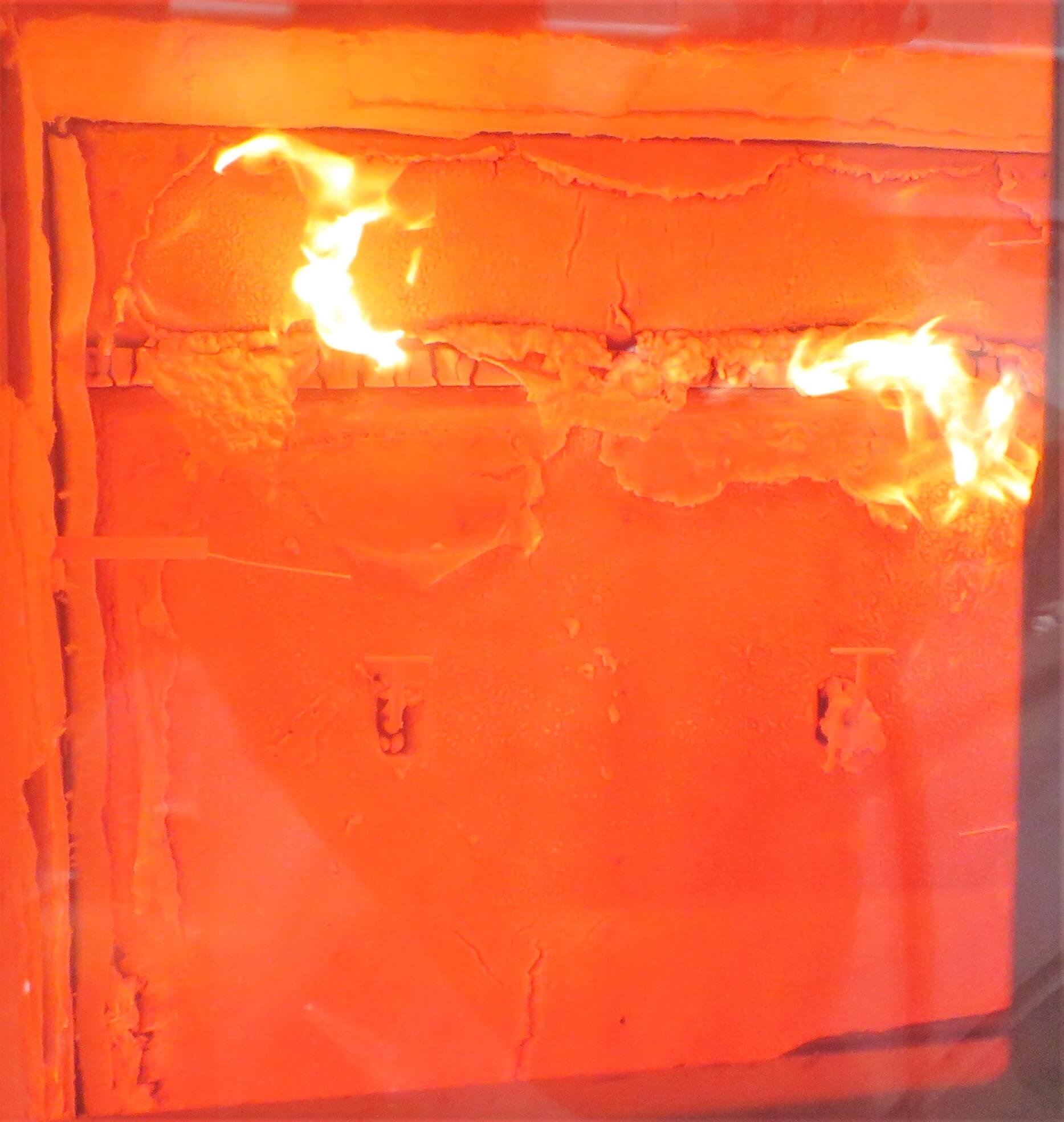

Our robust fire & research testing ensures reliability & compliance. Tech Coatings is committed to only provide intumescent coatings that are tested to international regulatory requirements. For our ongoing, robust testing regime we only work with the best accredited international fire laboratories.

Compliance through testing

Safety through certainty

Scenario Testing Regime

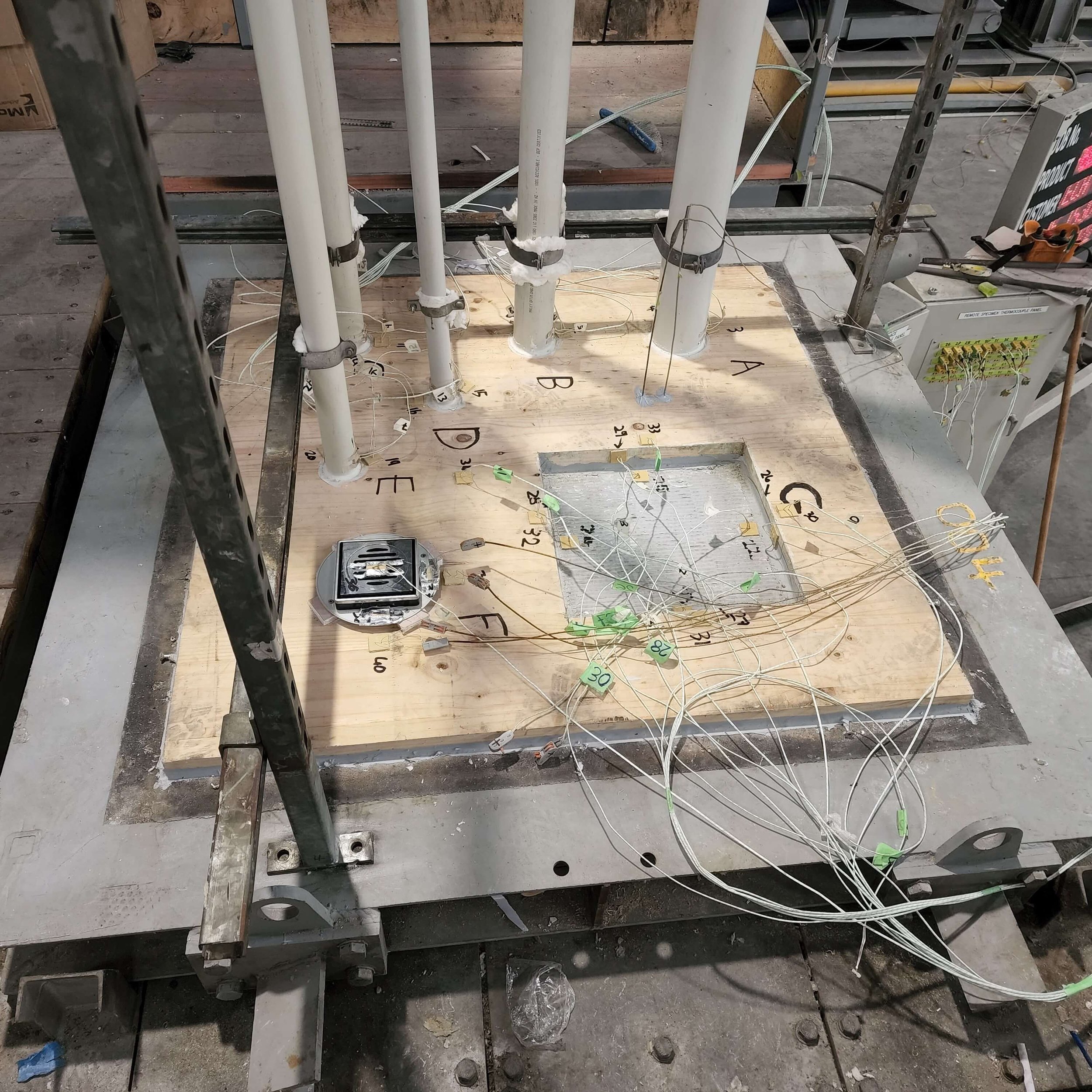

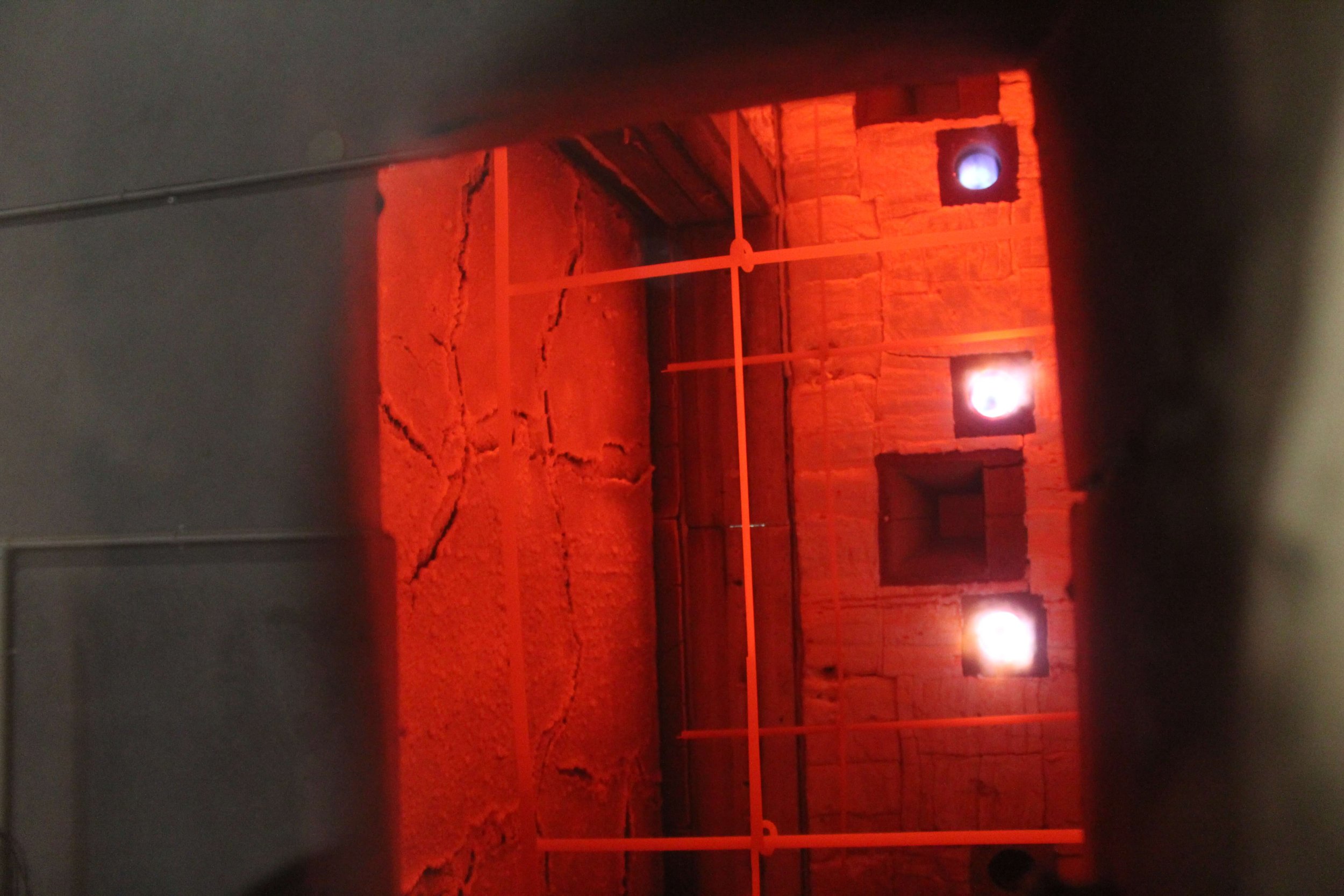

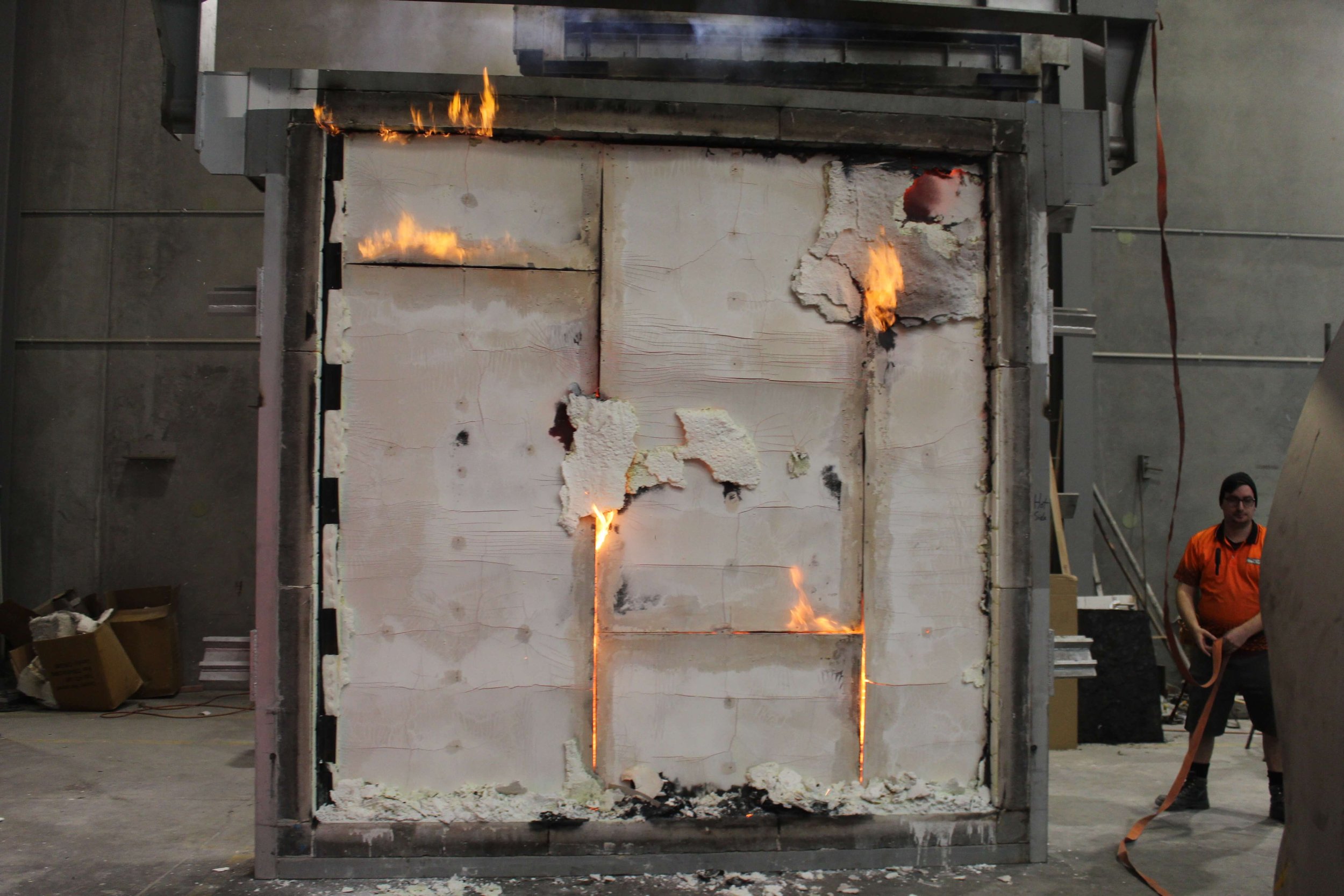

We regularly test and evaluate the performance of our intumescent coating systems to ensure they meet design specifications and regulatory requirements.

We perform full scale and research fire tests by “system”, rather than by separate component. These always include the substrate, our thin-film intumescent coating and depending on the system other elements like fire stopping or linings.

Actual knowledge

Testing gives actual knowledge, showing how the substrates used on site behave in a fire. It is our experience that test results can vary greatly from what calculations and models suggest e.g., the calculated char rate for soft timber is nearly double to what it is estimated to be at 0.65mm/min.

Actual knowledge, gained from actual fire tests, produces fire safety solutions that offer actual compliance

Innovation: Alternative solutions

Testing allows us to try innovative, substrate-specific solutions that can be accepted as alternative solutions (NZBC).

This way intumescent coating systems can e.g., be used for the encapsulation of structural mass timber members - an innovative approach with substantial benefits to the overall construction process and finished build.

Testing

overview

WHAT IS THE DIFFERENCE BETWEEN TESTS AND ASSESSMENTS?

Testing Fire Resistance Ratings

Our Passive Fire Protection systems start by having a specific system setup tested. As a result a certificate and test report is released by the independent testing authority, with the summarised results.

We test to AS 1530.4:2014 to receive a so called Fire Resistance Test. This is the document that sets out exactly what was tested and specifies the system that was used.

The result is expressed in three numbers as a Fire Resistance Rating e.g., 60/60/60 where the numbers, represent in minutes the structural adequacy, integrity and insulation.

Failure Criteria

AS 1540.4:2014 outlines the passing criteria for the three categories structural adequacy, integrity and insulation, and how to test them.

Structural adequacy fails when the test specimen collapses or the rate of deflection is too high.

Integrity fails when either there is continuous flaming on the non-fire side, a through gap into the furnace exceeds a certain size, or the ignition of the cotton wool pad test.

Insulation fails when the thermocouples on the non-fire side, exceed the prescribed limits.

Why are Assessments different?

Frequently situations arise where systems are required to be used in configurations that vary in some way from the original basic test configuration. These are known as assessments, because a suitably qualified person has had to make an ‘Assessment’ of the system’s suitability using information from existing test reports.

Any such varied systems approved as a result of formal opinions are referred to as “Tested & Assessed under AS 1530.4:2014”.

Systems used in the form originally tested will be referred to as, “Tested to AS 1530.4:2014”

PHOTO GALLERY:

VIDEO GALLERY:

Related articles

Dean Wall, Cake Commercial

“It is a pleasure to work with Tech Coatings, they think outside the box to offer compliant solutions, always relying on fire test data, which is such a crucial factor ”.

Want to know how our solution fits your project?

We’ve got you covered.